Decades of Forging Ahead

Focused on Friction Material R&D

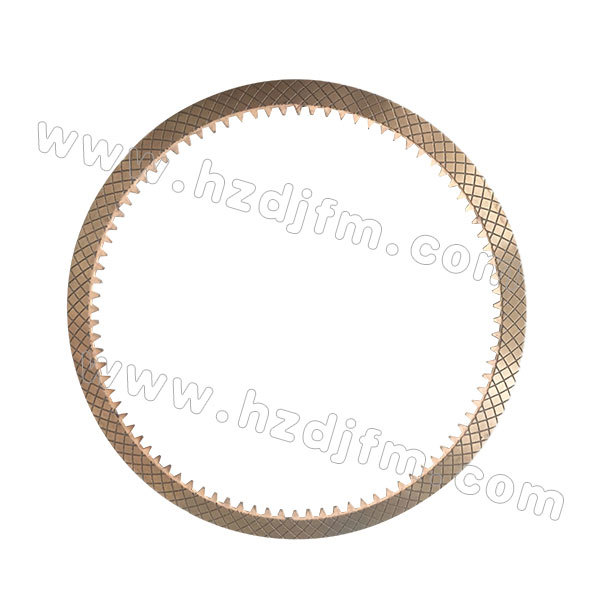

Hangzhou Dongjiang Friction Material was established in 2007. The company specializes in R&D, production, and sales of various powder metallurgy copper (iron)-based friction pads, asbestos-free paper-based friction pads, carbon-based friction pads, paired steel plates, semi-metallic friction products, and friction reduction material products. The products are widely used in clutches and brakes of construction, coal mining, agricultural and forestry machinery, forging machine tools, ships, automobiles, trains, elevators, and special vehicles.

Explore More

Explore More

Company Established in

Friction Pad Production

Specialized Equipment

Customer Praise

Applications

Friction plates are widely used in agricultural equipment for transmission systems and braking mechanisms, playing a crucial role in transmitting power, controlling rotational speed, and providing safe braking. For instance, in tractors, harvesters, and seeders, friction plates are integral to clutch assemblies, enabling smooth engagement and disengagement of power through frictional force, thus ensuring seamless equipment start-up, stoppage, and gear shifting. Additionally, in braking systems—such as those found in farm vehicles or large agricultural machinery—friction plates generate deceleration or bring the vehicle to a halt by creating friction against brake discs or drums, thereby enhancing operational safety. The materials used for these friction plates must exhibit exceptional resistance to high temperatures, wear, and corrosion, making them well-suited for the harsh, dusty, damp, or heavy-load environments typically encountered in field operations. Some advanced equipment now incorporates ceramic or sintered metal friction plates to further improve durability and performance stability, reducing maintenance frequency and ultimately boosting the reliability and efficiency of agricultural machinery.

Applications

Friction pads in the automotive industry are primarily used in braking and clutch systems, directly impacting driving safety and performance. 1. Brake Systems: Brake pads (friction pads) generate braking force by friction against the brake discs, enabling vehicles to decelerate or come to a stop. High-performance vehicles often employ ceramic or carbon-fiber composite materials to enhance heat resistance and braking stability, while minimizing thermal fade and noise. 2. Clutch Systems: Clutch friction plates transmit engine power to the transmission via the pressure plate, ensuring smooth gear shifts. Automatic transmissions, such as DCTs, also rely on multi-plate friction pad assemblies, which play a crucial role in shifting responsiveness and overall durability. 3. Development Trends: Traditional asbestos-based materials have been largely replaced by semi-metallic, organic (NAO), or sintered materials—each offering improved wear resistance and better suitability for the high-torque demands of new-energy vehicles. Looking ahead, smart friction materials, such as self-healing coatings, may further elevate performance and reliability.

Applications

Friction plates are widely used in industrial applications and serve as critical components in mechanical transmission and braking systems. They are commonly found in various types of machine tools, lifting equipment, construction machinery, and production lines, where they play a key role in clutches, brakes, and power transmission devices. By leveraging frictional forces, these plates enable precise control over equipment operations—enabling startups, stops, speed adjustments, and even overload protection. For instance, stamping machines rely on friction clutches to achieve accurate start-and-stop functions, while cranes depend on brake friction plates to ensure safe and reliable load management. Industrial friction plates must exhibit exceptional wear resistance, high-temperature tolerance, and corrosion resistance. To meet the demands of heavy-duty, high-frequency, or harsh operating conditions, they are typically manufactured from sintered metals, ceramics, or advanced composite materials. With the ongoing advancement of automation, smart friction materials—such as self-lubricating or sensor-integrated variants—are increasingly being incorporated into cutting-edge industrial equipment. These innovative materials not only enhance reliability but also boost energy efficiency, paving the way for more sophisticated and sustainable industrial solutions.

Applications

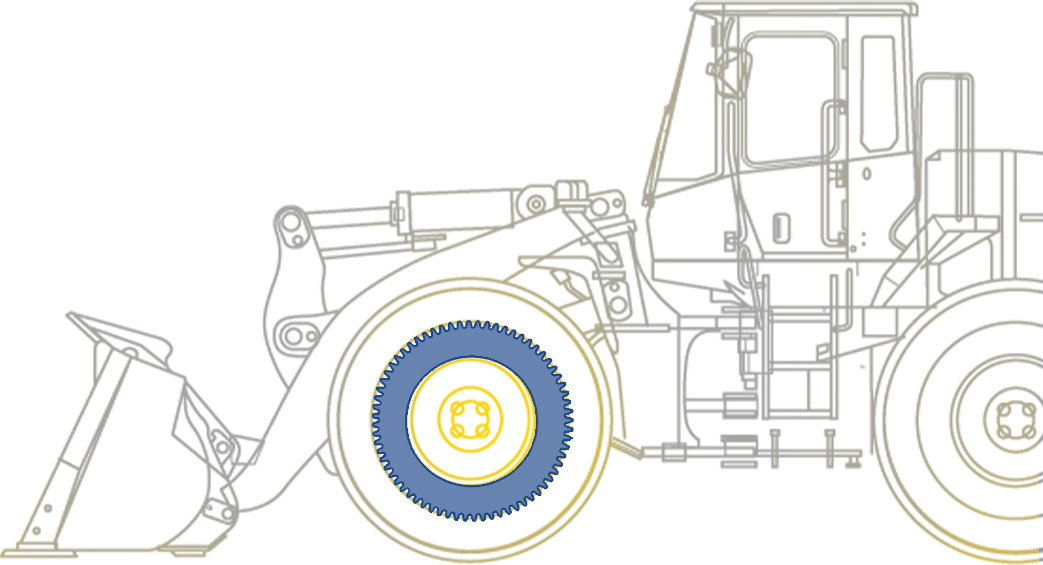

In construction and mining equipment, friction plates are critical components that ensure the safe and efficient operation of heavy machinery, primarily used in both transmission and braking systems. 1. Transmission Systems: Clutch friction plates in equipment like excavators and loaders are responsible for power transmission, enduring high-torque shocks in the process. They must exhibit exceptional wear resistance and thermal stability, typically made from sintered metals or reinforced composite materials. 2. Braking Systems: Mining trucks, cranes, and other heavy-duty vehicles rely on brake friction plates to achieve reliable deceleration or parking under extreme loads. These plates are designed to resist heat fade and minimize dust accumulation, often crafted from ceramic or carbon-based materials to handle harsh operating conditions. 3. Specialized Needs: For environments characterized by high levels of dust, moisture, or vibration, friction plates undergo anti-rust and anti-fouling treatments. Additionally, some advanced equipment incorporates intelligent wear-monitoring technologies to extend maintenance intervals and enhance overall safety.

Agricultural equipment

Automotive sector

Industrial Applications

Construction/Mining Equipment

Professional Manufacturer of Off-Road Vehicle

Friction Materials Enterprise

News & Information

Dongjiang

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Hotline

Address: 240 meters west of the intersection of Tangxin Line and Jianhua Road, Qiantang District, Hangzhou, Zhejiang Province

Email:HRdjmc@hzdjfm.com

Copyright © Hangzhou Dongjiang Friction Materials Co., Ltd. All rights reserved. Powered by www.300.cn