Product Introduction

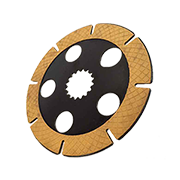

Paper-based friction materials are widely used in braking and transmission devices for construction machinery, agricultural machinery, and other industrial fields. They are made from heat-resistant fibers, fillers, and friction modifiers bonded with high-temperature resistant resin. Due to the special nature of the manufacturing process, customers can customize the materials to meet the specific requirements of various working conditions. Besides having a high friction coefficient, an extremely low static-to-dynamic friction ratio, smooth and gentle engagement without noise, paper-based materials can also exhibit high energy absorption capacity, excellent stability, durability, and the ability to withstand high pressure loads through adjustments in formulation and process parameters.

Paper-based friction materials are widely used in braking and transmission devices for construction machinery, agricultural machinery, and other industrial fields. They are made from heat-resistant fibers, fillers, and friction modifiers bonded with high-temperature resistant resin. Due to the special nature of the manufacturing process, customers can customize the materials to meet the specific requirements of various working conditions. Besides having a high friction coefficient, an extremely low static-to-dynamic friction ratio, smooth and gentle engagement without noise, paper-based materials can also exhibit high energy absorption capacity, excellent stability, durability, and the ability to withstand high pressure loads through adjustments in formulation and process parameters.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Hotline

Address: 240 meters west of the intersection of Tangxin Line and Jianhua Road, Qiantang District, Hangzhou, Zhejiang Province

Email:HRdjmc@hzdjfm.com

Copyright © Hangzhou Dongjiang Friction Materials Co., Ltd. All rights reserved. Powered by www.300.cn | Business Card